Technology

Mebius Packaging develops containers that are easy to use, as well as functional and

well-designed.

Many of the containers we have developed have received high ratings from external organizations and have

received awards in various national and international contests.

- Multi-layer Barrier Technology

(Olefin Bottles)

- Barrier Technology (PET Bottles)

- Decorative Technology

(Olefin Bottles)

- Easy-to-open Packages (Caps)

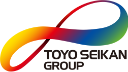

Multi-layer Barrier Technology (Olefin Bottles)

Lamicon bottle

Oxygen degrades food and other contents. The multi-layer bottle that combines resin

EVOH to be a barrier to oxygen with resins that are mainly olefins is called a "lamicon bottle."

We use this extensively for a variety of contents as a core technology of Mebius Packaging.

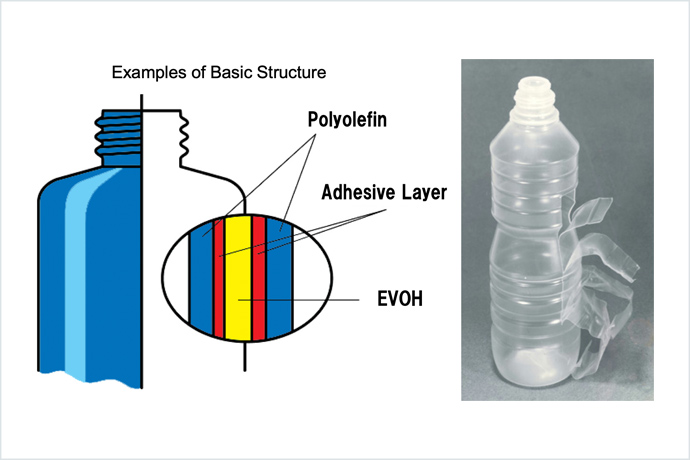

Multiblock

Oxygen degrades food and other contents. This is an olefin-based, multi-layer bottle

with oxygen absorption properties developed for the purpose of protecting the contents from

oxygen.

The use of our proprietary oxygen-absorbing material in the middle layer has dramatically increased

the oxygen-barrier performance of the container. Oxygen-absorbing material is sandwiched with EVOH

to retain oxygen-absorption performance for a long time.

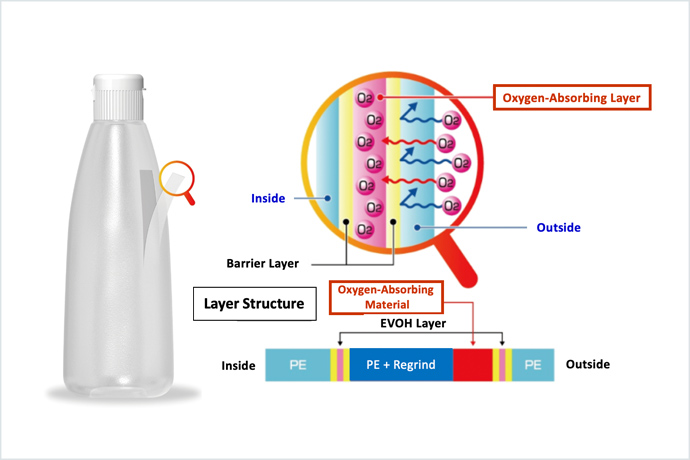

Barrier Technology (PET Bottles)

SiBARD

SiBARD is a double-layer, thin-film coated bottle that is coated on the inner surface

of a PET bottle with an organic silicon membrane having excellent flexibility and adhesion, and over

that a silicon oxide membrane (SiOx membrane) having an excellent gas-blocking property. This

two-layer technology is a technology unique to our Group. Furthermore, these containers have excellent

characteristics for gas-blocking properties and fragrance retention of the bottle contents.

They are colorless, transparent and hygienically excellent containers. With the use of a silicon-oxide

film, they have the effect of blocking gases that negatively affect the quality of foods including

oxygen, water vapor and carbonated gases.

Taking advantage of these characteristics, they have been widely used for oxygen-sensitive cooking

oils, and other such food products.

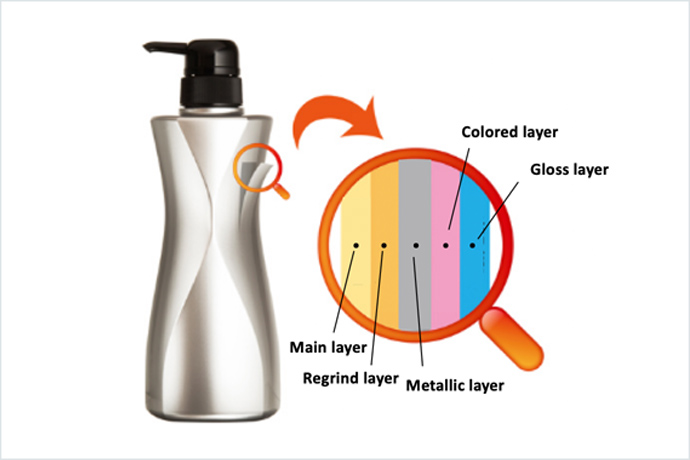

Decorative Technology (Olefin Bottles)

Prime Layer

What is Prime Layer?

Prime Layer is “Plastic bottle with a distinctive appearance " made by "multi-layer extrusion blow

molding technology", this is one of the core technologies of Mobius Packaging Co.,Ltd

Value

- Four types of design with different appearance.

- We can have Glossy and Matte appearance effect on the bottle

Features

① Glossy metallic bottle

This bottle has both a glass-like luster and a metallic feel, providing luxury.

② Matte metallic bottle

This bottle has both a glass-like luster and a metallic feel, providing luxury.

③ Glossy transparent bottle

This bottle has the highest transparency among olefin bottles.

④ Matt transparent bottle

This bottle can reproduce the appearance of frosted glass, providing luxury.

Metallic bottle

This is a metallic toned plastic bottle that is molded by only a direct blow method and spray paint is not used. Because it is highly eye-catching and has a luxurious feel, it is ideal for differentiating in areas where the design must be special, such as for hair care products, or the like.

Awards we have received

2019 Technical Packaging Award; Japan Packaging Institute (JPI)

This was adopted as a container for Scalp D made by the ANGFA Co., Ltd.

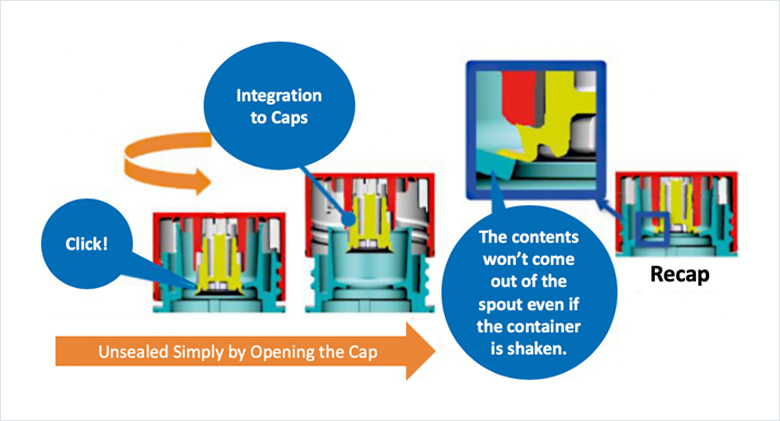

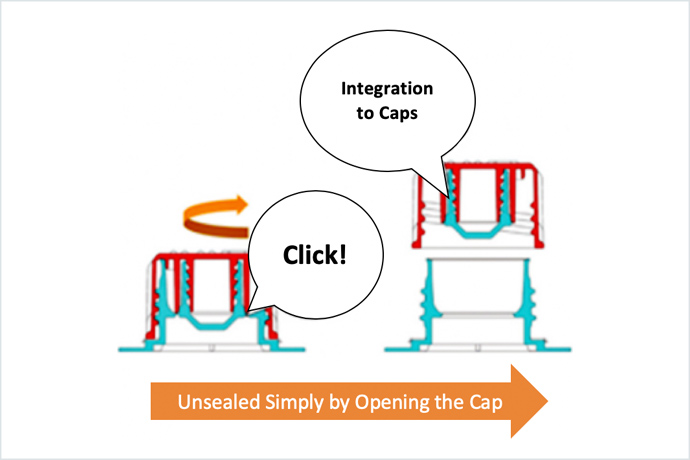

Easy-to-open Packages (Caps)

Pull-ring-less cap

This is a cap used for plastic bottles. Simply by turning the cap to open the bottle, this cap opens the inner plug with a clicking sound. The user does not need to pull on the inner plug pull-ring, as with conventional caps. Features include not causing pain to your fingers, the contents won’t splash out, and there is no waste.

Awards we have received

- 2018 Japan Packaging Institute (JPI) 2018 Food Packaging Department Award; Japan Packaging Contest

- 2018 Asian Packaging Federation (APF) Asian Star Contest 2018; Asian Star Award; Consumer Package Division

- 2019 World Packaging Organization (WPO); World Star Contest 2019; World Star Award; Food Division

- 2019 Japan Packaging Institute (JPI); 43rd Kinoshita Award New Creations Division

Joint award with Kewpie Corporation, Toyo Seikan Group Holdings Co., Ltd., Nippon Closures, and Mebius Packaging Co., Ltd.

This was adopted as a cap for a 180-ml container of "Kewpie Dressing" made by Kewpie Corporation.

Eiger Cap

This is a spout that can open the inner plug with a clicking sound simply by turning the cap to open at the spout of the liquid paper container. The user does not need to pull on the inner plug pull-ring, as with conventional caps. Features include not causing pain to your fingers, the contents won’t splash out, and there is no waste.

Awards we have received

2018 Japan Packaging Institute (JPI); 42nd Kinoshita Award New Creations Division

Joint award with Dai Nippon Printing Co., Ltd., and Mebius Packaging Co., Ltd.

This was adopted as a spout for a liquid paper container made by Dai Nippon Printing Co., Ltd.

Introduction to Each Award

Japan Packaging Contest

The Japan Packaging Contest is conducted with the aim of developing and popularizing excellent packaging and its technology. It is held annually under the auspices of the Japan Packaging Institute.

Japan Packaging Institute

Kinoshita Award

This award was created to commemorate the many years of achievements in the packaging industry of the late Matasaburo Kinoshita, the second president of the Japan Packaging Institute.

Asian Star Contest

Asian Star Award

This is held annually under the auspices of APF (Asian Packaging Federation) with the aim of introducing the world to excellent packaging from various countries in Asia. Only packages that have won national contests in respective countries are allowed to enter this award contest.

World Star Contest

World Star Award

Sponsored by WPO (World Packaging Organization), the World Star Contest is the only contest in the world to be held annually and to be judged for packaging in general, including from transport packaging to food and pharmaceutical packaging.